GEARBOXES

Here you will find extensive information about various types of applications, types, and innovations of gearboxes.

We offer a wide range of gearboxes that meet the specific needs of various industries.

Read on to learn more about our products and how they can make a difference in your applications, or contact us.

PLANETARY GEARBOXES

A planetary gearbox is a gearbox in which the input shaft and output shaft are in line. A planetary gearbox is used to transmit the highest torques on the smallest footprint. Buying a planetary gearbox can be a challenging task, given the many factors that come into play. When making your choice, it is important to consider a few things:

- Torque

- Power

- Speed

- Inertia

- Backlash

- Gear teeth

- Configuration

- Duty cycle

- Forces

- Investment

Apex Dynamics offers various series of gearboxes that are interchangeable and is ready to assist you in choosing the best planetary gearbox for your application.

EFFICIENCY OF A PLANETARY GEARBOXES

Durability and efficiency are crucial in modern drive systems. However, Apex Dynamics has implemented design features to achieve maximum efficiency, such as optimal sealing, polished gear teeth, and improved lubrication. As a result, a planetary gearbox can achieve an efficiency of 94-97%, compared to, for example, a worm-worm wheel gearbox with an efficiency of 50-75%. Discover the significance of efficiency in a planetary gearbox and why it is crucial for efficiency and durability in the article on the best efficiency for a gearbox.

PLANETARY GEARBOXES FOR INNOVATIVE TECHNOLOGIES

A planetary gearbox is an essential component of many innovative technologies, such as robots, 3D printers, and vehicles. It consists of a configuration of gears, including a sun gear, satellite gear, and planet gears. This composition allows a planetary gearbox to transmit high torques in a limited space. The origin of this mechanism dates back to Leonardo da Vinci in 1490. Check out the full article and see the operation and benefits of a planetary gearbox and how the gearbox originated.

Contact usRIGHT-ANGLE GEARBOXES

A right-angle gearbox usually consists of two sets of gears: bevel gears and spur gears. The bevel gears are used to change the rotation angle by 90 degrees, while the spur gears transmit the rotation to the output shaft. The design and configuration of the gears can vary depending on the application and the desired power and torque. Right-angle transmissions can also be used in combination with servo drives, although worm gear configurations have lower efficiency and, therefore, require a more powerful motor. In the article on right-angle gearboxes and right-angle transmission, there are deeper explanations and examples of how they work.

RIGHT-ANGLE GEARBOXES FOR VOLVO TRUCKS

Cofely Fabricom, a Belgian company specializing in technical installations, was asked to create a pre-assembly installation for truck axles at Volvo Trucks. When replicating the installation in the Swedish factory, a different gearbox was needed due to a different type of axle with a high weight. Apex Dynamics provided the solution with their right-angle gearboxes, which were compact, powerful, and quickly deliverable. Read how Apex Dynamics delivered right-angle gearboxes for axle positioning in Volvo Trucks.

Contact usSTAINLESS STEEL GEARBOXES

Apex Dynamics’ stainless steel gearboxes meet the strict technical and hygienic requirements of the food and packaging industries. Our standard range of gearboxes, including the AB, AD, AE, AF, and AT series, always have a stainless steel housing and output shaft, which is electrolytically nickel-plated. The precise specifications of our stainless steel reducers and the possibilities in terms of gearbox lubrication are further explained in the article on stainless steel gearboxes.

Apex Dynamics goes the extra mile for its customers, just like we did for the company Mydibel. Mydibel is a well-known manufacturer of potato products. One of their production machines had a servo drive with a gearbox that was overloaded due to the extremely high number of cycles per minute. We helped Mydibel by delivering an Apex Dynamics AB-series planetary gearbox that met the high specifications and had a standard stainless steel output shaft and housing.

Stainless steel is often a requirement in food-producing environments. Thanks to our solution, Mydibel was able to improve production efficiency, and consumers can enjoy delicious potato nuggets and noisettes. In the full article, we discuss the processes involved in delivering a stainless steel planetary gearbox to Mydibel.

STAINLESS STEEL GEARBOXES FOR HYGIENIC APPLICATIONS

Apex Dynamics supplies stainless steel gearboxes that perfectly match the innovative FLOW vertical form-fill-seal machine from GKS Packaging. The machine is designed with a quarter-circle shape and a completely hygienic design. Apex Dynamics’ AE-series planetary gearboxes are used for the foil feeding and the movement of the sealing bars. Discover the benefits of stainless steel gearboxes for hygienic applications!

contact usEXTENDED LIFESPAN GEARBOXES

Apex Dynamics offers a solution to extend the lifespan of gearboxes and prevent unnecessary replacements. Many customers replace gearboxes based on production hours, even if no deviations are observed during inspection. With the smart iQunet sensor, you can monitor gearboxes in real-time and replace them only when actual indications arise. Discover how Apex Dynamic’s iQunet sensor extends the lifespan of gearboxes with real-time monitoring.

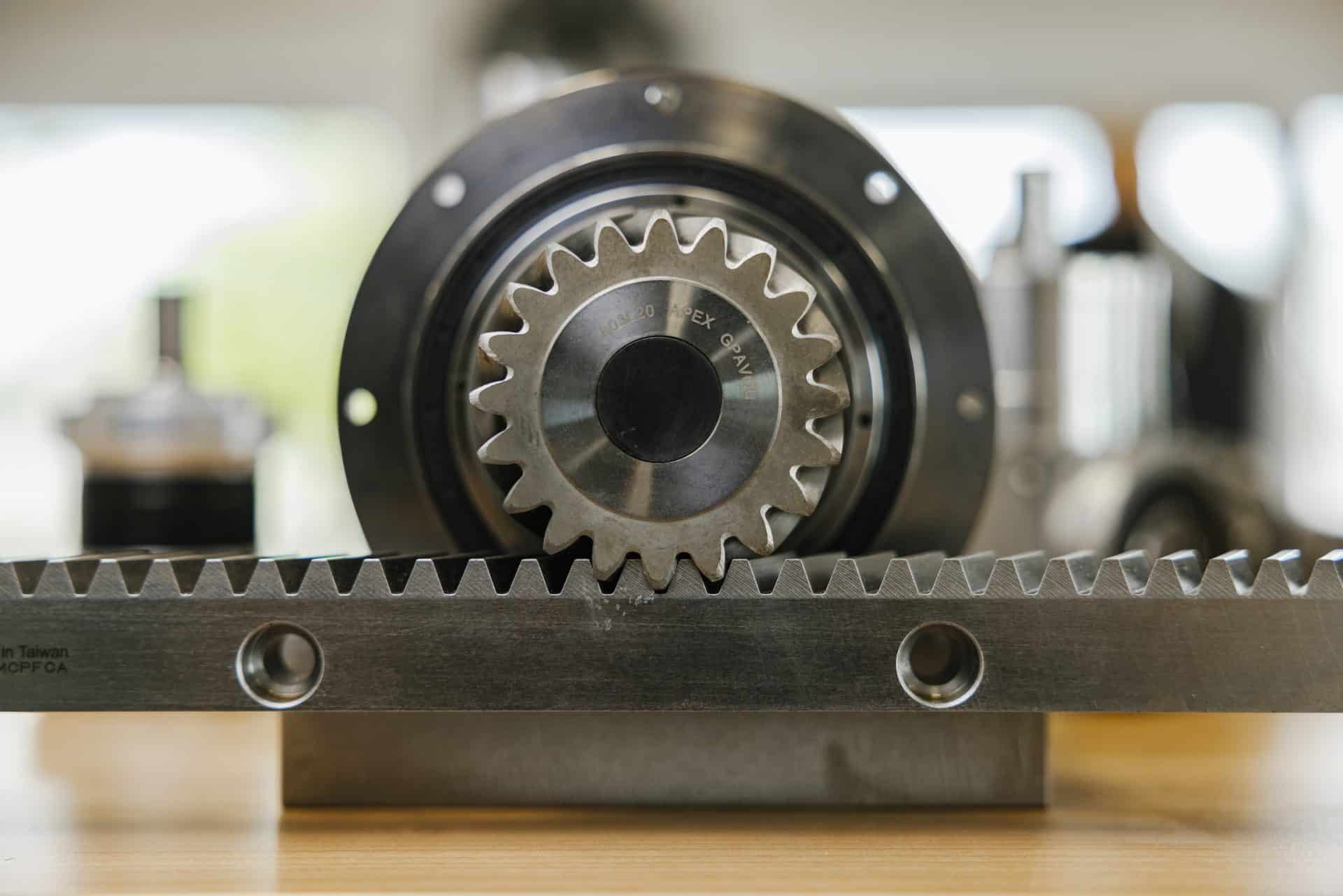

MOUNTING GEARBOXES

At Apex Dynamics, we understand the importance of maintaining flexibility in adjusting gearboxes. Sometimes, adjusting gearboxes requires very precise positioning, such as adjusting the pinion on a rack or aligning a complex structure. Therefore, we came up with a solution: the front plate with slotted holes. This allows you to precisely adjust the gearbox without fixing it in advance. In addition, the design with the axis close to the flange provides better support for radial forces. See the benefits of slotted holes and the flexible mounting of gearboxes with Apex Dynamics’ front plate.

Contact usCOAXIAL GEARBOXES

The coaxial gearboxes from Apex Dynamics’ AD and PD series are characterized by an output flange, a compact design, high torsional rigidity, and the ability to absorb radial and axial forces. The gearboxes are available in various sizes and ratios, fit any servo or stepper motor, and can be customized to specific customer needs. These coaxial gearboxes with hollow shafts have responded to the special request of machine builders because this product shape is ideal for compact machine designs and reduced components.

HOLLOW SHAFT GEARBOXES

Etracon, specialized in second-hand textile machines, has developed a machine for machine-knotting fringes in collaboration with Fidomatic. The machine uses Apex Dynamics’ ATB-type hollow shaft gearboxes.

The knotting machine is reliable, safe, and easy to adjust. With the help of 20 servo motors and 5 stepper motors, knots can be tied quickly and accurately, making the fringes look hand-knotted. With the added hollow shaft gearboxes from Apex Dynamics, the machine is ready to meet demand.

Contact usADVICE ON YOUR GEARBOXES

Are you unsure which gearbox is best suited for your application? Our experts are ready to help you make the right choice. They are available with extensive product knowledge and expertise based on years of experience. Contact us for personalized advice.

Neem contact op