ADR Series

Right angle planetary- Special design for continuous (S1) or cyclic (S5) duty operation

- Stainles steel housing, black anodized aluminum right angle housing and motor adapter flange

- Stainless steel output shaft, flange ISO 9409

- Helical gear technology

- Nominal Torques:

- T2N : 14 Nm - 2000 Nm

- Ratios

- 1-stage : 4 / 5 / 7 / 10 / 14 / 20

- 2-stage : 20 / 25 / 35 / 40 / 50 / 70 / 100 / 140 / 200

- *Only the ADR047 2-stage offers ratio 20 option.

- Low Backlash

- 1-stage: ≤ 2 arcmin / ≤ 4 arcmin / ≤ 6 arcmin

- 2-stage : ≤ 4 arcmin / ≤ 7 arcmin / ≤ 9 arcmin

- High Efficiency

- 1-stage : ≥ 95%

- 2-stage : ≥ 92%

- Easy mount

- Low noise

- Compact structure

- Sizes available: ADR047 / ADR064 / ADR090 / ADR110 / ADR140 / ADR200 / ADR255

|

Model No. |

Stage | Ratio1 | ADR047 | ADR064 | ADR090 | ADR110 | ADR140 | ADR200 | ADR255 | |

| Nominal Output Torque T2N | Nm | 1 | ||||||||

| 4 | 19 | 48 | 130 | 270 | 560 | 1,100 | 1,700 | |||

| 5 | 22 | 60 | 160 | 330 | 650 | 1,200 | 2,000 | |||

| 7 | 19 | 50 | 140 | 300 | 550 | 1,100 | 1,800 | |||

| 10 | 14 | 60 | 160 | 325 | 650 | 1,200 | 2,000 | |||

| 14 | - | 42 | 140 | 300 | 550 | 1,100 | 1,800 | |||

| 20 | - | 40 | 100 | 230 | 450 | 900 | 1,500 | |||

| 2 | 20 | 19 | - | - | - | - | - | - | ||

| 25 | 22 | 60 | 160 | 330 | 650 | 1,200 | 2,000 | |||

| 35 | 19 | 50 | 140 | 300 | 550 | 1,100 | 1,800 | |||

| 40 | 19 | 48 | 130 | 270 | 560 | 1,100 | 1,700 | |||

| 50 | 22 | 60 | 160 | 330 | 650 | 1,200 | 2,000 | |||

| 70 | 19 | 50 | 140 | 300 | 550 | 1,100 | 1,800 | |||

| 100 | 14 | 40 | 100 | 230 | 450 | 900 | 1,500 | |||

| 140 | - | - | 140 | 300 | 550 | 1,100 | 1,800 | |||

| 200 | - | - | 100 | 230 | 450 | 900 | 1,500 | |||

| Emergency Stop Torque T2NOT (2) | Nm | 1,2 | 4~200 | 3 times of nominal output torque T2N | ||||||

| Nominal Input Speed N1N | rpm | 1,2 | 4~200 | 5,000 | 5,000 | 4,000 | 4,000 | 3,000 | 3,000 | 2,000 |

| Max. input Speed N1B | rpm | 1,2 | 4~200 | 10,000 | 10,000 | 8,000 | 8,000 | 6,000 | 6,000 | 4,000 |

| Micro Backlash P0 | arcmin | 1 | 4~20 | - | - | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 | ≤ 2 |

| 2 | 25~200 | - | - | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ||

| Reduced BacklashP1 | arcmin | 1 | 4~20 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 | ≤ 4 |

| 2 | 25~200 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ≤ 7 | ||

| Standard BacklashP2 | arcmin | 1 | 4~20 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 | ≤ 6 |

| 2 | 25~200 | ≤ 9 | ≤ 9 | ≤ 9 | ≤ 9 | ≤ 9 | ≤ 9 | ≤ 9 | ||

| Torsional Rigidity | Nm/ arcmin |

1,2 | 4~200 | 7 | 13 | 31 | 82 | 151 | 440 | 1,006 |

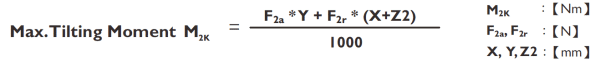

| Max. Tilting moment M2k | Nm | 1,2 | 4~200 | 55 | 75 | 190 | 300 | 1,300 | 2,930 | 5,500 |

| Max. Axial Load F2aB(3) | N | 1,2 | 4~200 | 990 | 1,050 | 2,850 | 2,990 | 10,590 | 16,660 | 29,430 |

| Efficiency | % | 1 | 4~20 | ≥ 95 % | ||||||

| 2 | 25~200 | ≥ 92 % | ||||||||

| Weight | kg | 1 | 4~20 | 1.1 | 2.1 | 5.9 | 10.5 | 21.9 | 50.9 | 85.4 |

| 2 | 25~200 | 1.4 | 1.9 | 4.5 | 9.8 | 20.1 | 45.4 | 85.9 | ||

| Operating Temperature | ºC | 1,2 | 4~200 | -10ºC ~+ 90ºC | ||||||

| Lubrication | 1,2 | 4~200 | synthetic gear grease | |||||||

| Degree of Gearbox Protection | 1,2 | 4~200 | IP65 | |||||||

| Mounting Position | 1,2 | 4~200 | all directions | |||||||

| Noise Level (4) | dB(A) | 1,2 | 4~200 | ≤ 61 | ≤ 63 | ≤ 65 | ≤ 68 | ≤ 70 | ≤ 72 | ≤ 74 |

- Ratio ( i = N in / N out )

- Applied to the output flange center at 100 rpm

- Maximum acceleration torque T2B = 60% van T2NOT

- These values are measured by gearbox with ratio 10 (1-stage) or ratio 100 (2-stage) at 3,000 rpm no loading.

By lower ratio and/or higher RPM, the noise level could be 3 to 5 dB higher.

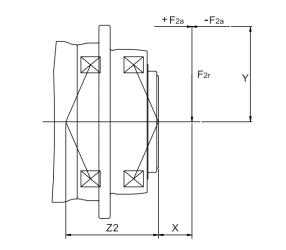

Maximum tilting moment:

| Size | ADR047 | ADR064 | ADR090 | ADR110 | ADR140 | ADR200 | ADR255 | |

| Z2 (mm) | 37.9 | 46.2 | 63.1 | 75.5 | 92.2 | 119.2 | 148.8 | |

Applied to the output flangecenter at 100 rpm

|

Model No. |

Stage | Ratio1 | ADR047 | ADR064 | ADR090 | ADR110 | ADR140 | ADR200 | ADR255 | |

| Mass Moments of inertia J1 | kg*cm2 | 1 | ||||||||

| 4~10 | 0.09 | 0.35 | 2.25 | 6.84 | 23.4 | 68.9 | 135.4 | |||

| 14 | - | 0.31 | 1.87 | 6.25 | 21.8 | 65.6 | 119.8 | |||

| 20 | - | 0.31 | 1.87 | 6.25 | 21.8 | 65.6 | 119.8 | |||

| 2 | ||||||||||

| 20 | 0.09 | - | - | - | - | - | - | |||

| 25~100 | 0.09 | 0.09 | 0.35 | 2.25 | 6.84 | 23.4 | 68.9 | |||

| 140~200 | - | - | 0.31 | 1.87 | 6.25 | 21.8 | 65.6 | |||

ADR series 1-stage, ratio i= 4~20

| ADR047 | ADR064 | ADR090 | ADR110 | ADR140 | ADR200 | ADR255 | |

| D1 H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D3 h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D4 h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D6 | 4 X M3 X 0.5P | 7 X M5 X 0.8P | 7 X M6 X 1P | 11 X M6 X 1P | 11 X M8 X 1.25P | 11 X M10 X 1.5P | 12 X M16 X 2P |

| D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D8 H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

| D10 | 8 X 3.4 | 8 X 4.5 | 8 X 5.5 | 8 X 5.5 | 12 X 6.6 | 12 X 9 | 16 X 13.5 |

| D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

| L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

| L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

| L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

| L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L8 | 107.5 | 126 | 172.5 | 201 | 263.5 | 334.5 | 392 |

| L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

| L10 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 |

| C1 1 | 46 | 70 | 100 | 130 | 165 | 215 | 235 |

| C2 1 | M4 X 0.7P | M5 X 0.8P | M6 X1P | M8 X 1.25P | M10 X 1.5P | M12 X 1.75P | M12 X 1.75P |

| C3 1 | ≤11 / ≤ 12 | ≤14 / ≤16 | ≤19 / ≤24 | ≤32 | ≤38 | ≤48 | ≤55 |

| C4 1 | 30 | 34 | 40 | 50 | 60 | 85 | 116 |

| C5 1 | 30 | 50 | 80 | 110 | 130 | 180 | 200 |

| C6 1 | 3.5 | 8 | 4 | 5 | 6 | 6 | 6 |

| C7 1 | 48 | 60 | 90 | 115 | 142 | 190 | 220 |

| C8 1 | 19.5 | 16 | 17 | 19.5 | 22.5 | 29 | 63 |

| C9 1 | 104.25 | 116.5 | 159.5 | 199 | 245.5 | 316 | 398.5 |

| C10 1 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 | 53.5 |

| C11 1 | 74 | 81.5 | 107.5 | 134 | 164.5 | 213.5 | 268.5 |

1. Dimensions are related to motor interface. Please contact Apex Dynamics for details

ADR series 2-stage, ratio i= 25~200

| ADR047 | ADR064 | ADR090 | ADR110 | ADR140 | ADR200 | ADR255 | |

| D1 H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D3 h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D4 h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D6 | 4 X M3 X 0.5P | 7 X M5 X 0.8P | 7 X M6 X 1P | 11 X M6 X 1P | 11 X M8 X 1.25P | 11 X M10 X 1.5P | 12 X M16 X 2P |

| D7 | 72 | 86 | 118 | 145 | 179 | 247 | 300 |

| D8 H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

| D10 | 8 X 3.4 | 8 X 4.5 | 8 X 5.5 | 8 X 5.5 | 12 X 6.6 | 12 X 9 | 16 X 13.5 |

| D12 | 46.2 | 63.2 | 89.2 | 109.2 | 139.2 | 199.2 | 254.2 |

| L1 | 4 | 8 | 12 | 12 | 12 | 16 | 20 |

| L2 | 6.5 | 8 | 13.5 | 13.5 | 17 | 22.5 | 30.5 |

| L3 | 3 | 3 | 6 | 6 | 6 | 8 | 12 |

| L4 | 19.5 | 19.5 | 30 | 29 | 38 | 50 | 66 |

| L5 | 7 | 7 | 10 | 10 | 14.6 | 15 | 20 |

| L6 | 4 | 4 | 7 | 8 | 10 | 12 | 18 |

| L8 | 122 | 132.5 | 163 | 217.5 | 269.5 | 333.5 | 403 |

| L9 | 4 | 6 | 7 | 7 | 7 | 10 | 10 |

| L10 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 |

| C1 2 | 46 | 46 | 70 | 100 | 130 | 165 | 200 |

| C2 2 | M4 X 0.7P | M4 X 0.7P | M4 X 0.7P | M6 X 1P | M8 X 1.25P | M10 X 1.5P | M12 X 1.75P |

| C3 2 | ≤11 / ≤ 12 | ≤11 / ≤12 | ≤14 / ≤15.875 / ≤16 |

≤ 19 / ≤ 24 | ≤32 | ≤38 | ≤48 |

| C4 2 | 30 | 30 | 30 | 40 | 50 | 60 | 85 |

| C5 2 | 30 | 30 | 50 | 80 | 110 | 130 | 180 |

| C6 2 | 3.5 | 3.5 | 8 | 4 | 5 | 6 | 6 |

| C7 2 | 48 | 48 | 60 | 90 | 115 | 142 | 190 |

| C8 2 | 19.5 | 19.5 | 19 | 17 | 19.5 | 22.5 | 29 |

| C9 2 | 103.25 | 108.25 | 128.25 | 166.5 | 209 | 269.5 | 340 |

| C10 2 | 13.25 | 13.25 | 13.5 | 10.75 | 13 | 15 | 20.75 |

| C11 2 | 74 | 74 | 81.5 | 107.5 | 134 | 164.5 | 213.5 |

2. Dimensions are related to motor interface. Please contact Apex Dynamics for details.

Dimensions Output Flange ( ISO 9409 )

| Dimension | ADR047 | ADR064 | ADR090 | ADR110 | ADR140 | ADR200 | ADR255 |

| D1 H7 | 12 | 20 | 31.5 | 40 | 50 | 80 | 100 |

| D2 | 20 | 31.5 | 50 | 63 | 80 | 125 | 140 |

| D3 h7 | 28 | 40 | 63 | 80 | 100 | 160 | 180 |

| D4 h7 | 47 | 64 | 90 | 110 | 140 | 200 | 255 |

| D5 | 67 | 79 | 109 | 135 | 168 | 233 | 280 |

| D6 | M3 x 0.5P | M5 x 0.8P | M6 x 1P | M6 x 1P | M8 x 1.25P | M10 x 1.5P | M16 x 2P |

| D8 H7 | 3 | 5 | 6 | 6 | 8 | 10 | 12 |

| D10 | 3.4 | 4.5 | 5.5 | 5.5 | 6.6 | 9 | 13.5 |