PL series

In line planetary- Black coated steel housing, aluminum output and motor adapter flange

- Steel output shaft, special for belt pulley

- Spur gear design

- Nominal torques:

- T2N : 27 Nm - 143 Nm

- Ratios

- 1-stage : 3 / 4 / 5 / 7 / 10

- 2-stage : 12 / 15 / 16 / 20 / 25 / 30 / 35 / 40 / 50 / 70 / 100

- Low backlash

- 1-stage : ≤ 6 ~ 7 arcmin

- 2-stage : ≤ 8 ~ 9 arcmin

- High efficiency

- 1-stage : ≥ 97%

- 2-stage : ≥ 94%

- Easy mount

- Compact structure

- Sizes available: PL 070 / PL 090 / PL 120

PL |

Stage | Ratio (1) | PL 070 |

PL 090 |

PL 120 |

|

|

Nominal output torque T2N |

Nm |

1 |

3 | 30 | 67 | 107 |

| 4 | 39 | 86 | 137 | |||

| 5 | 40 | 89 | 140 | |||

| 7 | 37 | 80 | 128 | |||

| 10 | 27 | 59 | 93 | |||

|

2 |

12 | 31 | 69 | 109 | ||

| 15 | 31 | 70 | 110 | |||

| 16 | 39 | 86 | 137 | |||

| 20 | 39 | 88 | 141 | |||

| 25 | 40 | 89 | 140 | |||

| 30 | 32 | 72 | 111 | |||

| 35 | 36 | 80 | 130 | |||

| 40 | 41 | 92 | 143 | |||

| 50 | 42 | 90 | 143 | |||

| 70 | 37 | 81 | 131 | |||

| 100 | 27 | 59 | 93 | |||

| Emergency stop torque T2NOT | Nm | 1,2 | 3~100 | 3 times nominal output torque T2N | ||

| Max. Acceleration torque T2B | Nm | 1,2 | 3~100 | T2B = 60% of T2NOT | ||

| No load running torque (2) | Nm | 1 | 3~10 | 0.1 | 0.4 | 0.8 |

| 2 | 12~100 | 0.1 | 0.3 | 0.4 | ||

| Backlash (3) | arcminutes | 1 | 3~10 | ≤ 7 | ≤ 6 | ≤ 6 |

| 2 | 12~100 | ≤ 9 | ≤ 8 | ≤ 8 | ||

| Torsional rigidity | Nm/arcmin | 1,2 | 3~100 | 2.2 | 8 | 12 |

| Nominal input speed n1N | rpm | 1,2 | 3~100 | 4,000 | 3,600 | 3,600 |

| Max. input speed n1B | rpm | 1,2 | 3~100 | 6,000 | 6,000 | 4,800 |

| Max. radial load F2rB (4) | N | 1,2 | 3~100 | 2,600 | 3,100 | 6,550 |

| Max. axial load F2aB (4) | N | 1,2 | 3~100 | 1,300 | 1,550 | 3,275 |

| Max. tilting moment M2k | Nm | 1,2 | 3~100 | 50 | 65 | 180 |

| Operating temperature | °C | 1,2 | 3~100 | 0° C ~ +90°C | ||

| Degree of Protection | 1,2 | 3~100 | IP65 | |||

| Lubrication | 1,2 | 3~100 | Synthetisch lubrication grease | |||

| Mounting position | 1,2 | 3~100 | All directions | |||

| Running noise (2) | dB (A) | 1,2 | 3~100 | ≤ 62 | ≤ 64 | ≤ 66 |

| Max. belt tension | N | 1,2 | 3~100 | 560 | 950 | 1200 |

| Max. bending moment based on input flange Mb (5) | Nm | 1,2 | 3~100 | 19 | 38 | 45 |

| Efficiency n | % | 1 | 3~10 | ≥97% | ||

| 2 | 12~100 | ≥94% | ||||

- Ratio ( i = N in / N out )

- These values are measured by gearbox with ratio 10 (1-stage) or ratio 100 (2-stage) at 3.000 rpm no loading.

By lower ratio and/or higher RPM, the noise level could be 3 to 5 dB higher - Backlash is measured at 2% of Nominal output torque T2N.

- Applied to the ourput flange center at 100 rpm.

- Max. motor weight* (kg) = (0.1 x Mb) / (motor length (m))

*with symmetrically distributed motor weight

*with horizontal and stationary mounting

| Model No. | PL 070 | PL 090 | PL 120 | ||||

| Ø (A) (C3) | 1-stage | 2-stage | 1-stage | 2-stage | 1-stage | 2-stage | |

| 8 | kg•cm2 | 0.12 | 0.10 | - | - | - | - |

| 11 | 0.19 | 0.16 | - | - | - | - | |

| 14 | 0.22 | 0.20 | 0.36 | 0.24 | - | - | |

| 19 | 1.53 | 1.51 | 1.70 | 1.58 | 2.20 | 1.73 | |

| 24 | - | - | 2.24 | 2.12 | 2.74 | 2.27 | |

| 28 | - | - | 2.68 | 2.55 | 3.17 | 2.70 | |

| 32 | - | - | - | - | 7.77 | 7.30 | |

| 35 | - | - | - | - | 10.80 | 10.30 | |

| 38 | - | - | - | - | 14.00 | 13.50 | |

| 42 | - | - | - | - | - | - | |

(A) Ø Input shaft diameter

PL series:

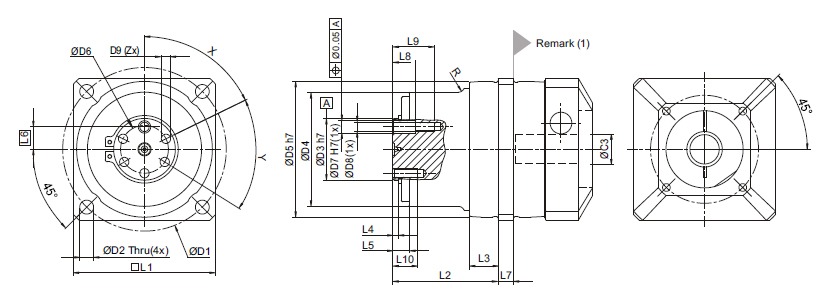

| Dimensions | PL 070 | PL 090 | PL 120 | |||

| 1-stage | 2-stage | 1-stage | 2-stage | 1-stage | 2-stage | |

| D1 | 82 | 106 | 144 | |||

| D2 | 6.6 | 9 | 13 | |||

| D3 h7 | 25 | 40 | 50 | |||

| D4 | 58 | 74 | 100 | |||

| D5 h7 | 68 | 88 | 118 | |||

| D6 | 18 | 31 | 37 | |||

| D7 H7 | 6 | 8 | 147 | |||

| D8 | M5 x 0.8P | M6 x 1P | M6 x 1P | |||

| D9 | M5 x 0.8P | M6 x 1P | M8 x 1.25P | |||

| R | - | 4 | 2 | |||

| L1 | 70 | 92 | 122 | |||

| L2 | 60.2 | 68.3 | 82.2 | |||

| L3 | 12.7 | 18.3 | 15.7 | |||

| L4 | 3.8 | 3.7 | 4.5 | |||

| L5 | 10 | 10.5 | 12.5 | |||

| L6 | 8.8 | 14.5 | 18.5 | |||

| L7 | 8 | 10 | 12 | |||

| L8 | 10 | 15 | 16 | |||

| L9 | 18.5 | 27 | 28 | |||

| L10 | 12 | 16 | 16 | |||

| X in graden | 64° | 45° | 45° | |||

| Y in graden | 58° | 45° | 45° | |||

| Z | 5 | 7 | 7 | |||

(1) Input dimensions vary according to motor flange. Please contact Apex Dynamics for details.

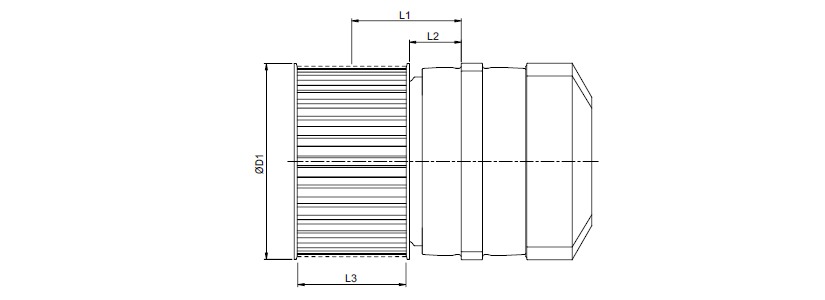

Pulley dimensions

Gearbox |

Belt Pulley | D1 |

L1 |

L2 |

L3 |

Pitch P |

number of teeth Z |

Circumference Z*P |

Inertia J |

Mass m |

| mm | mm/rotation | kg/cm2 | kg | |||||||

PL 070 |

AT05-W50-T43 | 71 | 41.8 | 14.8 | 51 | 5 | 43 | 215 | 4.68 | 0.57 |

| HTD 5M-W50-T44 | 72.9 | 41.8 | 14.8 | 51 | 5 | 44 | 220 | 5.58 | 0.65 | |

| 5GT-W50-T44 | 72.9 | 41.8 | 14.8 | 51 | 5 | 44 | 220 | 5.58 | 0.65 | |

PL 090 |

AT10-W50-T28 | 91.7 | 51.3 | 24.3 | 51 | 10 | 28 | 280 | 14.07 | 1.00 |

| HTD 8M-W50-T36 | 98.4 | 51.3 | 24.3 | 51 | 8 | 36 | 288 | 17.78 | 1.18 | |

| 8YU-W50-T36 | 98.4 | 51.3 | 24.3 | 51 | 8 | 36 | 288 | 17.78 | 1.18 | |

PL120 |

AT20-W75-T19 | 124.6 | 57.7 | 17.7 | 76 | 20 | 19 | 380 | 69.55 | 2.71 |

| HTD 14M-W75-T28 | 137 | 57.7 | 17.7 | 76 | 14 | 28 | 392 | 87.83 | 3.20 |

Pulley ordering code

PUL0701 - AT052 - B3

(1) Pulley size.

(2) Pulley specification

(3) Pulley appearance:

B = Manganese phosphate blackening (standard)

N = Nickel plating