Green Team Twente tests planetary gearbox at high speeds

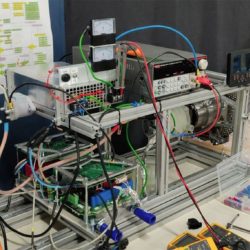

How does our AE210-015 planetary gearbox perform at increased speeds? An award-winning student team from Twente wants to use our planetary gearbox in the transmission system of their new hydrogen-powered race car. But our planetary gearbox is not primarily designed for input speeds of 10,000 rpm. A test rig shows whether the planetary gearbox can be used in this groundbreaking race car.

Green Team Twente is a multidisciplinary student team with students from the University of Twente and Saxion Hogeschool. They are committed to developing and applying technological innovations in the field of sustainable mobility. In the coming years, the team will grow from 22 full-time and 6 part-time students in 2022 to 30 full-time students in 2023.

For the 11th year of Green Team Twente – for the past three years their car has been one of the world’s most efficiently driving hydrogen-powered cars – the team opted for a new challenge. The student team stops participating in the Shell Eco Marathon and enters the Formula Student world. They want to show what Green Team Twente is capable of by developing and building the world’s first hydrogen-powered Formula Student race car.

To take steps quickly (and save money), the team works together as much as possible with companies with knowledge, experience and products that fit the challenge.

Planetary Gearbox out of Specification

Test method

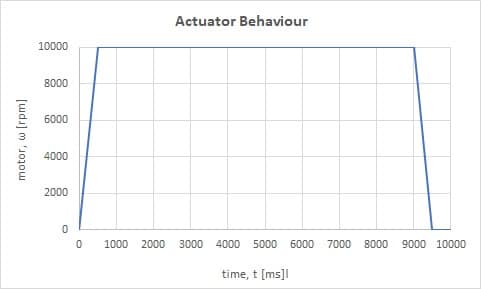

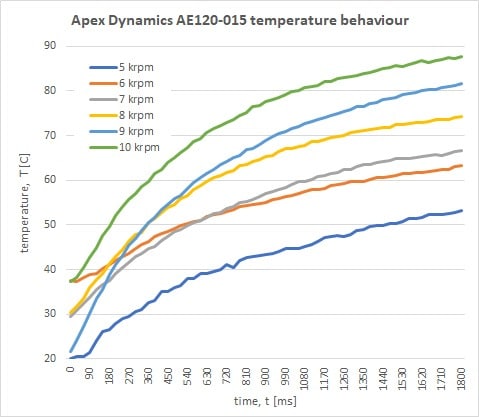

The test method used to test the planetary gearbox has a linear structure with increasing speed. By maintaining a constant cycle for a period of time, temperature measurements were taken and a comparison could be made.

- Acceleration time: 1.000 ms

- Peak time: 7.500 ms

- Deceleration time: 1.000 ms

- Down time: 500 ms

A temperature reading was taken every 30 seconds, the tests are performed at the following speeds:

- 5.000 rpm

- 6.000 rpm

- 7.000 rpm

- 8.000 rpm

- 9.000 rpm

- 10.000 rpm

The specified input speeds of an AE120-015 are nominally 4,000 rpm and maximum 8,000 rpm.

Indications on mechanical failures

With regard to noise levels, no significant increase in noise levels was observed over the duration of the experiments. This indicates that the transmission lubrication was able to function well enough.

Conclusion

Conclusion

To answer our research question “Will the APEX DYNAMICS AE120-015 planetary gearbox operate within normal specifications at elevated speeds”, it can be confirmed that the temperature of 90 °C is not exceeded. Not even at the highest speeds of 10.000 rpm.

Explanation:

The reason that the APEX DYNAMICS AE120-015 gearbox remains relatively cool under high speeds is 3-fold:

- The input bearing rotates with the output shaft, causing it to rotate at a relative speed.

- At the input side, the bearing and seal are separated from each other, so that we can seal at the smallest possible diameter. This gives the lowest circumferential speed and lowest heating.

- The pump rings on the planetary gears ensure lubrication of it’s bearings.

Do you also have an application outside specification?

Contact APEX DYNAMICS and we will find a solution together!

Conclusion

Conclusion