Helical and bevel gear gearbox offers solution for Swedex

Swedex had to deal with a ‘broken’ transmission ratio, which caused rounding errors in its fully automatic soldering machines. The developer, manufacturer and marketer of circular saw blades contacted Apex Dynamics for a solution. In this article we explain why the worm gear gearbox caused problems and what the result was of the solution provided.

Swedex had to deal with a ‘broken’ transmission ratio, which caused rounding errors in its fully automatic soldering machines. The developer, manufacturer and marketer of circular saw blades contacted Apex Dynamics for a solution. In this article we explain why the worm gear gearbox caused problems and what the result was of the solution provided.

At first glance, a saw blade can be seen as a relatively simple product. But appearances are deceiving; the product undergoes several steps in a precise production process. Swedex specifically develops products for the worldwide wood, aluminum, plastics and metal processing industries. It is not surprising that Swedex employs around 250 employees in Jönköping, Sweden.

During one of the important steps in the production process – the soldering – a structural problem occurred and the manufacturer contacted Apex Dynamics for a solution.

Accurate positioning is crucial when soldering saw blades

When soldering, the hardened tooth (saw blade insert) is attached to the seats of the handle blade with silver solder. Several types of silver solder are used, but the most common variety is a three-layer silver solder consisting of a copper core surrounded by a silver mixture. Three-layer silver solder is used because it offers the advantage of reducing the risk of tooth cracking during the soldering process itself.

Soldering is a precision job where the tooth is held still within a few hundredths of a millimeter while it is heated to over 700°C. They use fully automatic soldering machines with robot charge for an efficient production process. An accurate drive is therefore crucial.

Worm gear gearbox with ‘broken’ gear ratio

Helical and spiral bevel gear gearbox is the solution

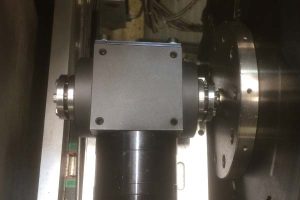

In the Apex program, the 7.5 : 1 specific ratio is not available. That is why 2 gearboxes have been mounted in series, first an AB060 with 5 : 1 and then an ATB090FC with 1.5 : 1, giving a total transmission ratio of 7.5 : 1. The AB060-005 is a helical-toothed High-End gearbox, The ATB090FC is a spiral-bevel gearbox with helical teeth and an output shaft with shrink disk for backlash-free transmission. The result was satisfactory: much higher precision, shorter cycle times and readjustments are a thing of the past.

Thanks to the APEX Dynamics products, Swedex can now keep this machine running with high precision for many years to come.

Source: Apex Dynamics Sweden AB and Swedex AB