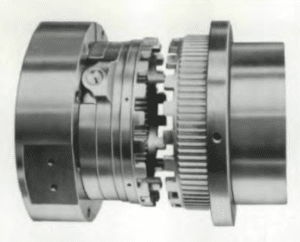

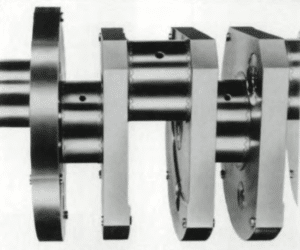

Pinion with Curvic Plate coupling

Apex Dynamics introduced pinions with a Curvic coupling in 2016 in response to a clear market demand. The main reasons for this development were :

- in order to be able (always) to change the pinion of the drive afterwards (FLEXIBILITY),,

- to have a backlash-free, centered connection (ACCURACY), and

- to have about 20 teeth on the pinion (LOADABILITY).

Specifications Curvic plate coupling

But if it brings such large benefits, why don’t we see this type of coupling more often?

The main reasons for this are that high-quality machines, high-quality materials and highly trained personnel are required to produce a good Curvic coupling. We therefore see these couplings in demanding markets such as aerospace and energy plants.

The origin of the Curvic plate coupling

The principle of this coupling was invented by the very successful German engineer Albert Hirth (1858 – 1935). He started the companies Norma Compagnie GmbH (ball bearings, later taken over by SKF), Fortuna Werke (packaging machines) and KACO (Seals for the automotive), in addition to his Hirth AG (camshafts and gears). In his life he applied for more than 350 patents and was therefore called the “Swabian Edison”. At the age of 73 he applied for a patent for a “four-color pen with one-hand operation”. Don’t we all know that one?

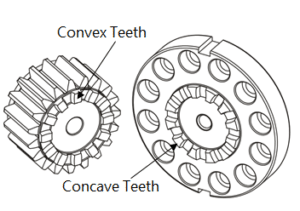

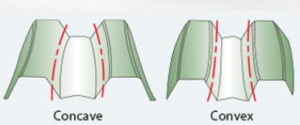

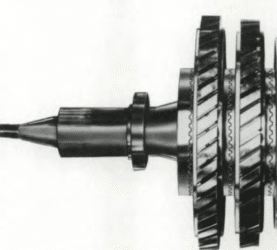

The development of the Curvic coupling stems directly from the production of spiral conical gears, which were made on the same machines and with similar production methods. The term “Curvic” refers to cams on a circle that have a characteristic curved shape when viewed perpendicular to the coupling.

The three basic types of Curvic couplings are

- fixed Curvic coupling

- semi-universal coupling

- disconnect coupling

In all cases, this type of coupling offers good precision centering, a high load-bearing capacity and it is free of backlash.

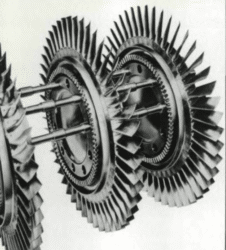

Fixed Curvic plate couplings

The fixed Curvic coupling is a high-precision rigid connection of two elements. The fixed Curvic coupling is widely used in the construction of built-up turbine and compressor blades for air and space crafts and industrial gas-steam turbines. Crankshafts can be made from individual, interchangeable parts through this coupling. The fixed Curvic coupling is also used by many large machine manufacturers for precision indexing mechanisms.

|

|

|

Semi-universal curvic plate couplings

The semi-universal coupling is also a precision coupling but is loosely coupled to allow a maximum of 2 degrees of skew of axes together with an axial play. The teeth of one part usually have a curved profile to keep the load centered and to transmit an almost uniform movement.

Curvic plate disconnect coupling

The decoupling couplings are designed and made in such a way that the correct ‘tooth contact’ is maintained while the coupling switches on and off. In the larger sizes, a spiral-shaped surface is used to achieve this. For small couplings, this action is approached by a specially located tooth bearing. The two parts of a switch or overload coupling are usually held in place by spring pressure. Switch couplings are nowadays used in a large number of applications, including cars, agricultural machines and tool changers. Couplings can be produced by sawing or grinding, depending on the required accuracy.

For more information about Curvic-plate pinions, please contact Apex Dynamics.