GV/GVR-series gearboxes for AGV’s

Apex Dynamics introduces a new series of gearboxes specifically designed for AGV applications. The GV/GVR series combines an ultra-compact design with high torsional rigidity, high torque, and a radial load capacity of up to 14,500 N. The result is precise, reliable motion in demanding logistics and industrial environments—exactly what autonomous vehicles need for 24/7 operation.

What does AGV stand for

AGV stands for Automated Guided Vehicle: vehicles that operate without human intervention in a controlled environment, such as a warehouse, factory, or distribution center. They move pallets, bins, and boxes, perform loading and unloading tasks, and ensure a predictable, constant flow of materials. Thanks to their availability and safety, AGVs are the backbone of modern intralogistics. The drivetrain of such a vehicle is constantly under load and must be compact and rigid to fit within tight construction spaces and be positioned precisely. This is precisely where the GV/GVR series excels.

AGV stands for Automated Guided Vehicle: vehicles that operate without human intervention in a controlled environment, such as a warehouse, factory, or distribution center. They move pallets, bins, and boxes, perform loading and unloading tasks, and ensure a predictable, constant flow of materials. Thanks to their availability and safety, AGVs are the backbone of modern intralogistics. The drivetrain of such a vehicle is constantly under load and must be compact and rigid to fit within tight construction spaces and be positioned precisely. This is precisely where the GV/GVR series excels.

Why the GV/GVR series is the logical choice for AGV’s

-

Super compact construction

- With mounting space from approximately 35 mm, the series is ideal for low-profile vehicles and tight wheel modules.

- Available in straight (GV) and right-angle (GVR) versions, allowing you to easily design around the vehicle layout and center of gravity.

- Three sizes with ratios i = 22.5 and i = 31.5 cover a wide range of speed and torque requirements.

-

Maximum stiffness and high torque

- The first stage is equipped with four satellite gears, providing exceptional strength and torsional rigidity.

- Hardened sun and planet gears deliver high torque and a long service life, even with frequent start-stop cycles and direction changes.

- A rotating satellite gear ensures optimal force distribution and even load distribution, essential for accuracy and low wear.

-

Efficient and energy-saving

- High efficiency and optimized moment of inertia reduce energy consumption and extend battery life, crucial for autonomous systems.

- Low vibration and quiet: ideal for 24/7 businesses where comfort, safety, and predictability are paramount.

-

Robust load capacity

- Radial load capacity up to 14,500 N ensures reliable wheel and roller drive, even with varying floor conditions, thresholds, tight curves, and uneven loads.

- High torsional stiffness translates into precise steering and repeatable positioning accuracy during docking and line tracking.

-

Fast integration and ease of maintenance

- Apex Dynamics provides an integrated adapter plate, ensuring a perfect fit without additional spacers or improvisation.

- An optional frame-mounting bracket speeds installation, alignment, and service.

- A plug-and-play servomotor interface shortens the design-to-deployment time.

Suitable AGV applications

The GV/GVR series is designed for reliable, predictable motion in compact vehicles. Its combination of stiffness, load capacity, and efficiency makes it suitable for a wide range of applications.:

- Pallet transport AGV’s: move EU and block pallets between inbound, storage, and shipping. The high radial load capacity supports robust wheels, even with varying floor conditions.

- Shuttle and tote AGV’s: compact vehicles for containers, boxes, and micro-fulfillment. The minimal installation height of the GV/GVR fits perfectly in flat platforms and under racking.

- Tugger AGV’s (tractors): pull carts or trains with variable masses. The high torque and torsional stiffness improve traction, stability, and accuracy during coupling and uncoupling.

- Machine loading AGV’s: automatically load and unload CNC machines, packaging lines, or assembly cells. The rigid first stage with four satellite wheels supports repeatable and precise docking.

- Cold storage and freezer AGV’s: use in low temperatures requires grip and wear resistance. The available Hytrel wheels with a wide temperature range deliver performance in cold environments.

- AGV’s for oven and heat zones: with the right wheel selection, driving characteristics remain predictable at higher temperatures; mechanically, the GV/GVR offers stable performance.

- Distribution center shuttles: many cycles, short stops, and countless direction changes. Here, the high efficiency and optimized moment of inertia make a direct difference in energy consumption and uptime.

- Positioning for overhead cranes: drive to position a central lifting point above a load. The combination of torque and stiffness supports precise, repeatable alignment.

Features and specifications of the GV/GVR series

- Three sizes with gear ratios i = 22.5 and i = 31.5, available in straight (GV) and right-angle (GVR) versions.

- Super compact: installation space from approximately 35 mm for maximum design freedom in tight wheel modules.

- First stage with four satellite gears for maximum strength and torsional rigidity.

- Rotating satellite gear ensures optimal force interaction and even loading of the gears.

- Hardened sun and planet gears deliver high torque, a long service life, and predictable behavior in cyclic operation.

- High efficiency and optimized moment of inertia for energy-efficient drive and extended battery life.

- High torsional rigidity ensures precise positioning, stable driving behavior, and reproducible trajectories.

- Radial load capacity up to 14,500 N: robust for wheel and roller applications in logistics and production.

- Optional mounting bracket for easy frame installation and serviceability.

- Available with three different wheel materials for optimum grip, wear resistance and temperature resistance.

Wheel materials: grip, precision and durability

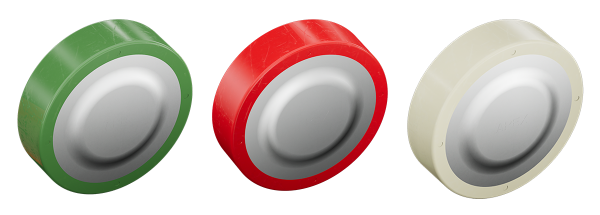

For AGV’s, the choice of material determines grip, wear, temperature behavior, and positioning accuracy. Apex Dynamics offers three material options, each with its own profile.:

| Type | A | B | C |

| Colour | Green | Red | Beige |

| Hardness | 64 Sh-D | 98 Sh-A | 64 Sh-D |

| Hardnees feels like | Car tire | Skateboard wheel | Car tire |

| Feature material | General – lots of grip and low surface pressure | Hard – precise positioning | Grip – wide temperature range |

| Temperature range | -30 to +120 degrees C | -30 to +100 degrees C | -50 to +150 degrees C |

| Wear resistance | ++ | ++ | +++ |

| Application | Distribution centers | Machine positioning | Cold stores and ovens |

Short selection assistance

- Versatile, high-grip, and low floor pressure: Type A (soft TPU).

- Maximum precision and precise steering: Type B (hard TPU).

- Cold or warm zones and high durability: Type C (Hytrel).

Integration: quickly from design to deployment

To accelerate implementation, Apex Dynamics offers the GV/GVR gearbox with an integrated adapter plate. The motor fits directly, without additional spacers, keeping tolerance chains short and maximizing build space. An optional mounting bracket is available for mounting in tight AGV frames, simplifying installation, alignment, and service. In practice, this means reduced engineering time, a lower risk of assembly errors, and faster commissioning.

Key integration benefits:

- Plug-and-play servomotor flanges and bolt patterns for common motors.

- Straight or angled options available based on vehicle layout, wheel position, and center of gravity.

- Sealed components and appropriate lubrication ensure a long service life in dusty or temperature-critical environments.

- Maintenance-friendly design reduces downtime during service intervals.

Frequently Asked Questions (FAQ)

- What distinguishes the GV/GVR series in AGV use?

- The combination of ultra-compact design, high torsional stiffness (due to four satellite wheels in the first stage), and radial load capacity of up to 14,500 N makes the GV/GVR ideally suited for wheel and roller drives. You get precise positioning and reliable handling, even during intensive cycles.

- What gear ratios are available?

- The standard gear ratios are i = 22.5 and i = 31.5, available in both straight (GV) and right-angle (GVR) versions, across three sizes. This allows you to easily tailor speed, torque, and space to your application.

- Which wheel materials should I choose for my environment?

- Soft TPU (A) is versatile and provides excellent grip with low floor stress. Hard TPU (B) offers maximum precision and control for positioning work. Hytrel (C) excels in wear resistance, chemical resistance, and a wide temperature range (−50 to +150°C), ideal for cold stores and hot areas.

- Can you connect motors directly?

- Thanks to the integrated adapter plate, common motors fit seamlessly onto the gearbox. This shortens lead time and minimizes the number of fitting parts.

- Can you assist with dimensioning and layout?

- We advise on load, cycles, acceleration, thermal aspects, wheel material, and mounting. Based on your use case, we can quickly propose a suitable GV/GVR configuration.

In summary: why GV/GVR for your AGV

- Compact: Installation space from approximately 35 mm for maximum design freedom.

- Powerful and rigid: Four satellite wheels in the first stage, hardened gears, and high torsional rigidity.

- Efficient: High efficiency and optimized moment of inertia for extended battery life.

- Robust: Radial load capacity up to 14,500 N and low-vibration handling.

- Flexible: Straight (GV) and Right-Angle (GVR), i = 22.5 and 31.5, three sizes, three wheel materials.

- Quick to integrate: Integrated adapter plate and optional mounting bracket.

Contact and advice

Want to know which GV/GVR configuration and wheel choice best suits your AGV application? Or do you have questions about integration, delivery times, or documentation? Contact Apex Dynamics for a customized proposal.