Jakom increases accuracy of 23-meter lathe with AP series gearboxes

With the AP series gearboxes, Jakom obtained a high-precision solution for renovating the slide drive of an impressive 23-meter-long Wohlenberg lathe. The application demonstrates how a low-backlash drive contributes to higher positioning accuracy and process stability at extreme lengths. This article focuses on the chosen solution and explains how this project was realized, from the technical challenge to the final application.

With the AP series gearboxes, Jakom obtained a high-precision solution for renovating the slide drive of an impressive 23-meter-long Wohlenberg lathe. The application demonstrates how a low-backlash drive contributes to higher positioning accuracy and process stability at extreme lengths. This article focuses on the chosen solution and explains how this project was realized, from the technical challenge to the final application.

About Jakom: Specialist in shafts and rollers

Since 1986, Jakom Cuijk B.V. has been a passionate and specialized manufacturer of shafts, rollers, and liners for a wide range of industries, including oil & gas, maritime, energy, hydraulics, and mechanical engineering. From their high-tech factory in Cuijk, they execute projects worldwide, from propeller shafts for naval vessels to components in paper pulp mills and installations in Australia and Siberia. In short, Jakom operates in a niche market with little room for concessions.

Since 1986, Jakom Cuijk B.V. has been a passionate and specialized manufacturer of shafts, rollers, and liners for a wide range of industries, including oil & gas, maritime, energy, hydraulics, and mechanical engineering. From their high-tech factory in Cuijk, they execute projects worldwide, from propeller shafts for naval vessels to components in paper pulp mills and installations in Australia and Siberia. In short, Jakom operates in a niche market with little room for concessions.

- Lathes for products up to 23 meters in length, 2,000 mm in diameter, and 40 tons in weight.

- A multitask machine with a machining length of 18 meters and a maximum weight of 64 tons.

- Two unique straightening machines for shafts and tubes up to 25 meters in length.

- Dynamic balancing facilities for products up to 12 meters in length, 3 tons in weight, and 1,600 mm in diameter.

The material palette is broad: from carbon steel and heat-treated steel to stainless steel, titanium, super duplex, and other specialty alloys. The organization is focused on high accuracy and reproducibility, supported by ISO 9001 certification and an in-house QC department with a measuring room where all final inspections are performed.

This infrastructure forms the foundation for customization at the highest level, but also requires drive technology that offers the same precision and reliability.

Renewal of the linear slide guide

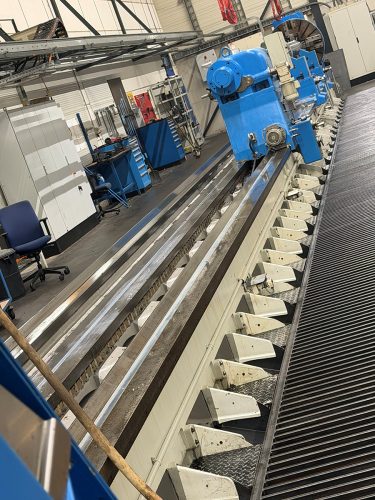

Hessel Hendriks, co-owner of Jakom, decided to modernize an existing Wohlenberg lathe with a bed length of 23 meters. The goal was to update the slide drive to achieve higher positioning accuracy and process stability. The AP series gearboxes from Apex Dynamics, known for their high accuracy and low-backlash operation, were chosen for the drive.

The gearboxes were combined with Siemens servo motors in a master-slave configuration. Module 5 helical pinions with a Curvic Plate mounting were used for the transmission. To ensure maximum accuracy, accelerate assembly, and efficiently transfer forces to the machine frame, hardened and ground racks with a length of 2,000 mm were chosen.

Each drive delivers approximately 2,600 Nm of torque, resulting in a feed force of approximately 56,000 N. This gives the lathe extremely rigid and precise longitudinal movement, matching the scale and requirements of Jakom’s products.

Power of AP series gearboxes in mechanical engineering

For Apex Dynamics, this application further underscores the strength of our AP series in heavy-duty, precision machine building applications. Would you also like advice on low-backlash and high-precision drives?

Then contact Apex Dynamics.