Introduction

Thank you for your interest in our quotation tool. APEX Dynamics has specially developed this tool to serve you as a customer even faster and more easy.

Questions or comments are always welcome!+31 (0)492 509 995 (NL) / +32 (0)3 808 15 62 (BE) or contact us per mail

Volgende stap

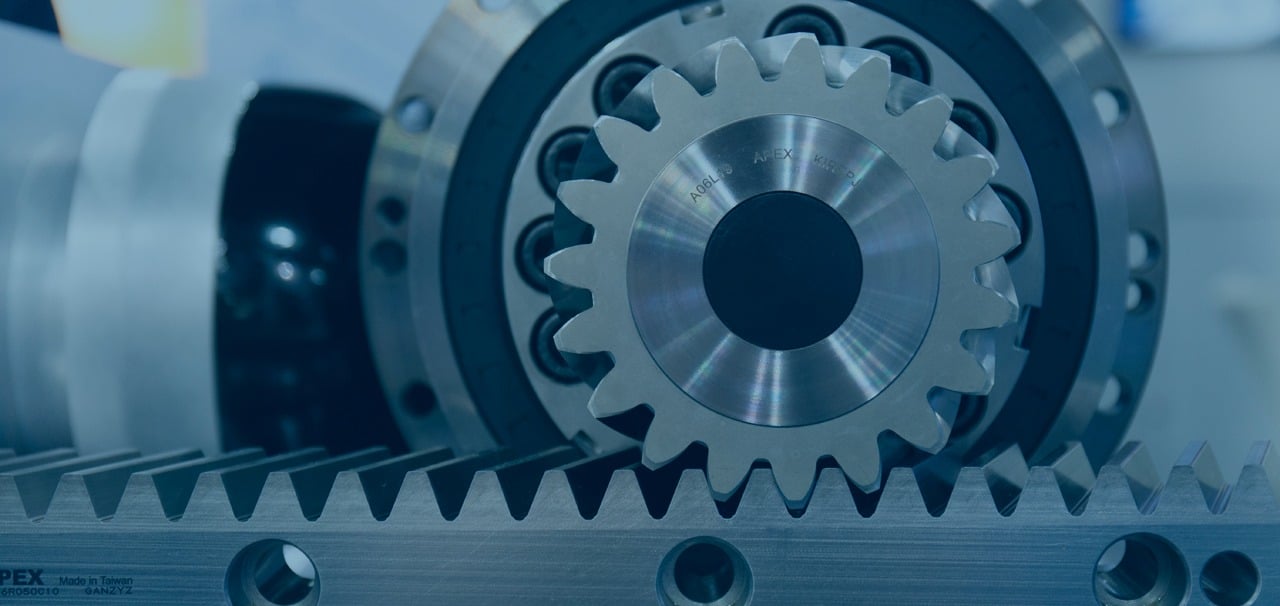

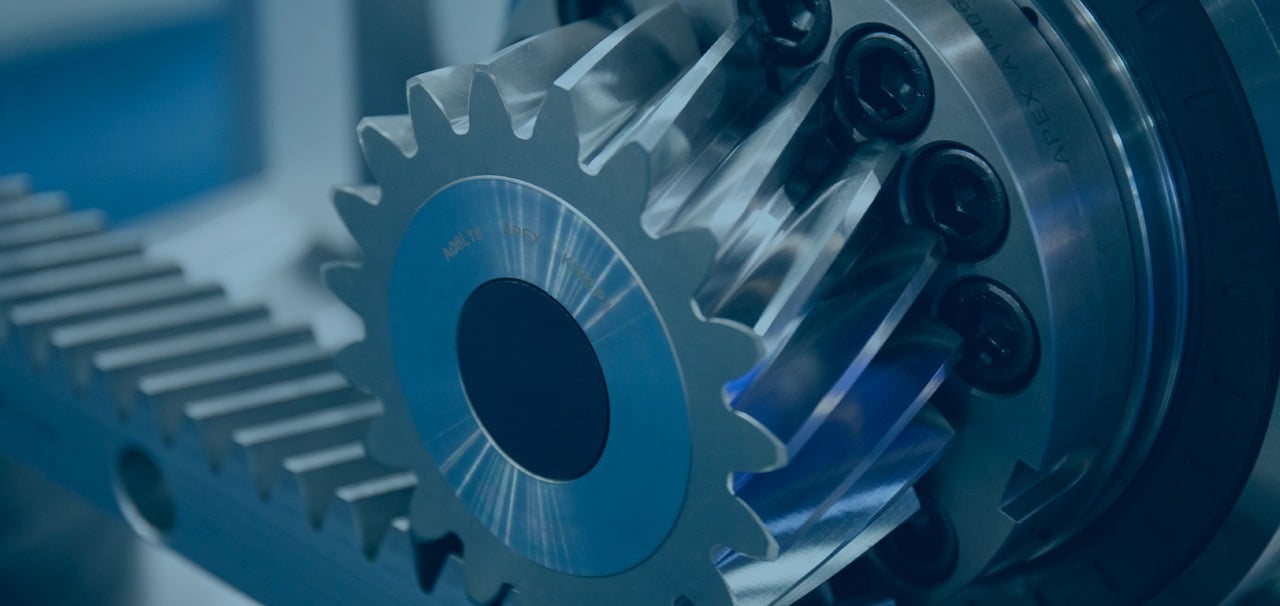

Straight or Right-Angled

All our straight (spur) gearboxes are also available in a right-angle (90°) version. This can save space in the application. The bevel gear and hypïode gearboxes are of course always right-angled.

Choose here which execution is preferred:

Volgende stap

Output shaft

Apex Dynamics has no less than 8 options regarding the output shaft, select the desired version here: output shaft without key (S1), output shaft with key (S2), output involvente or spline shaft (S3, DIN 5480), output flange (ISO 9409), output flange with curvic plate (patented), output shaft for a belt pulley (pulley available separately), output hollow shaft with keyway or output hollow shaft with shrink disk.

Volgende stap

Specifications

Enter the desired backlash (in ≤ X arcminutes), ratio (ratio X:1) and the required Nominal output torque (Nm) ?

Volgende stap

Material

Apex Dynamics has 3 choices regarding the material of the housing. This is inherent for the type of gearbox, so it is not always a free choice. The adapter plates (for mounting the motor used) are standard always made of aluminum, stainless steel is an option.

Stainless (SUS416) : AB/ABR. AD/ADR/ADS, AE/AER, AF/AFR, AFX/AFXR, AT

Volgende stap

Additional information

Which motor will be mounted?

Because we always supply a suitable motor adapter plate, suitable input diameter and motor mounting material, we need to know which (servo) motor is being mounted. Specify the brand and type of the motor here.

Lubrication

As standard we supply all our gearboxes with a synthetic lubricant (grease), but we can also supply with other specific lubricants such as: Food Grade (NSF-H1), Low temperature, Grease (High Speed), Vacuum lubricant or even without lubricant. A surcharge will be charged for this.

Select lubrication

Standard

Food Grade (NSF-H1)

Grease

Low temperature

Vacuum lubricant

No smeermiddel

I do not know

Quantity

How many piece do you require in this configuration?

Volgende stap

Application

In order to get the best possible picture of the application, we request you to enter a description and preferably a drawing (or sketch)?

Description of the application

Offerte opvragen!