Apex Dynamics is extending range of flange gearboxes

Gearboxes from Apex Dynamics are an excellent replacement for other brand gearboxes, and not only because of our very short delivery times. We continuously work on the application range of our gearboxes, racks and pinions. Recently we took another big step in this expension: we have now five different series of low backlash gearboxes with an ISO 9409 flange output (robot flange).

Gearboxes from Apex Dynamics are an excellent replacement for other brand gearboxes, and not only because of our very short delivery times. We continuously work on the application range of our gearboxes, racks and pinions. Recently we took another big step in this expension: we have now five different series of low backlash gearboxes with an ISO 9409 flange output (robot flange).

Common applications that use this mounting method are delta robots, stroke tables and rack systems, but also less accurate applications such as AGV drives. And with 5 series the customer can always select the optimal gearbox, for example the backlash, straight or right-angle, hollow shaft, curvic plate pinion, stainless steel, steel or aluminum, ratio and dynamic behaviour.

We will explain all the advantages individually per series. If you have any questions after that, we will gladly help you personally.

Benefits of mounting a gearbox with flange

Benefits of mounting a gearbox with flange

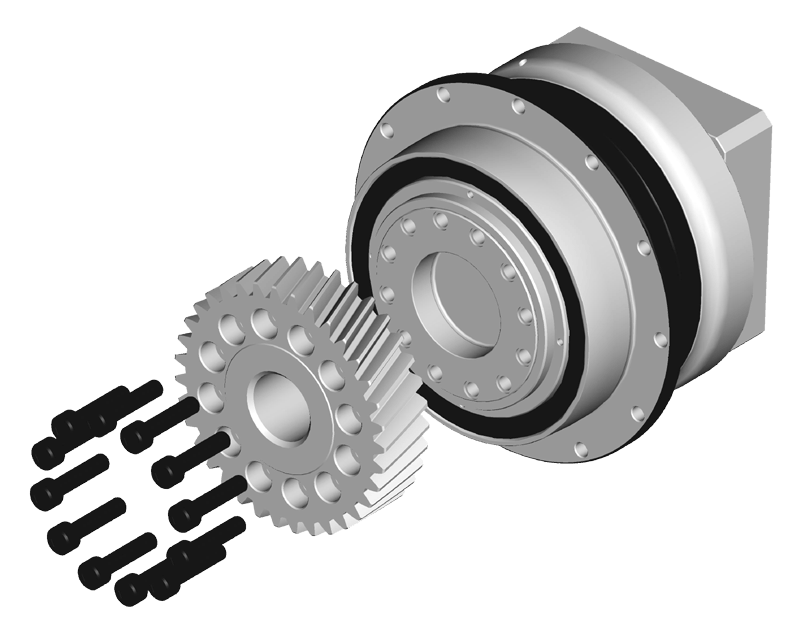

Mounting on a flange instead of on a shaft has a number of advantages:

- Higher torques, often the shaft – especially the keyway – is the limiting factor.

- Higher bending moments and radial forces due to the generally larger bearings.

- Compact construction, because there is no output shaft.

- Form closed mounting instead of force closed mounting (shaft with clamping hub).

Application for a gearbox with output flange

The gearboxes with outout flange are often used in high-precision applications, such as:

The gearboxes with outout flange are often used in high-precision applications, such as:

- Robotics, for example Delta-robots.

- Takt tables, to make very accurate steps. For example, in filling installations.

- Rack systems, in use with a pinion. For example in laser cutting machines.

But also in less accurate applications, such as driving an AGV.

ISO 9404 guarantees interchangeability of the mechanical interface of the gearbox

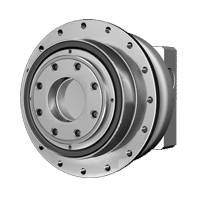

Low backlash gearboxes with ISO 9404 output flange

Because we have 5 different gearboxes with an output flange, you’ll find a short overview below so you can make the right choice faster:

|

|

|

|

|

|

|

|

|

||

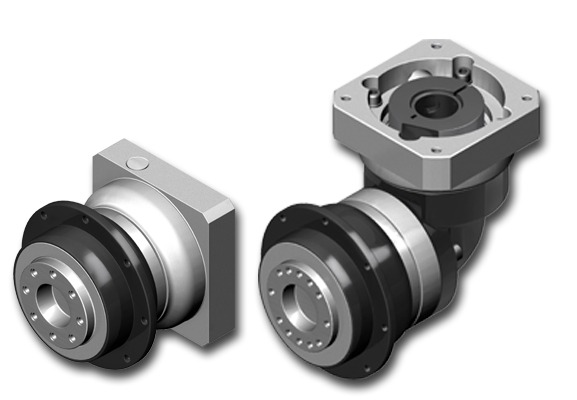

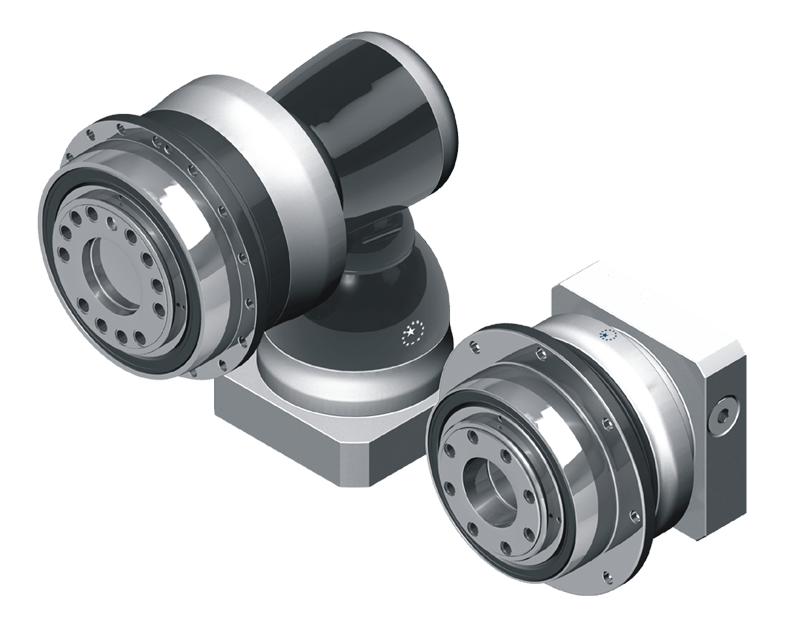

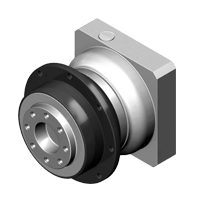

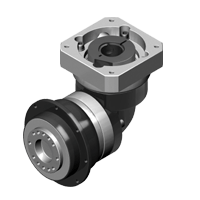

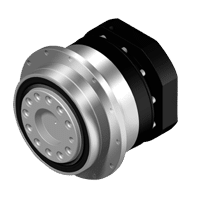

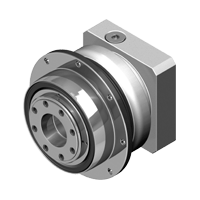

| PD / PDR | AD / ADR | KH | AH / AHK | AP / APK | ||||||

| Classification | Medium-end | High-end | High-end | High-end | High-Torque | |||||

| Toothing | Spur | Helical | Helical | Helical | Helical | |||||

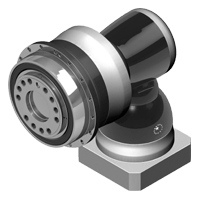

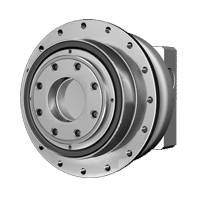

| Type | Planetary, right-angle with bevel gear | Planetary, right-angle with bevel gear | Hypoïd, possibly with planetary pre-stage | Planetary, right-angle with hypoïd stage | Planetary, right-angle with hypoïd stage | |||||

| Backlash | < 6 arcminutes | < 5 up to < 1 arcminutes | < 3 arcminutes | < 1 arcminute | < 1 arcminute | |||||

| Material | Steel and Aluminum | Stainless steel and Aluminum | Steel and Aluminum | Steel and Aluminum | Steel and Aluminum | |||||

| Nominal Torques | Up to 232 Nm | Up to 2.000 Nm | Up to 1.600 Nm | Up to 10.915 Nm | Up to 14.010 Nm | |||||

| Ratio | 3:1 – 100:1 | 3:1 – 200:1 | 3:1 – 100:1 | 4:1 – 10.000:1 | 5,5:1 – 5.500:1 | |||||

| Dynamics | Medium | High | High | High | Very High | |||||

| Execution | Straight and right-angle | Straight and right-angle | Right-angle | Straight and right-angle | Straight and right-angle | |||||

| Remarks | Also with hollow shaft | Also with Curvic-plate® flange | ||||||||

If you want to apply a flange gearbox in your application and you do have questions about which type to use, please contact Apex Dynamics BV. We are happy to advise you the right type of gearbox, the size, ratio and possibly also the motor to mount and / or the pinion to mount.