Calculate current limitation for gearboxes

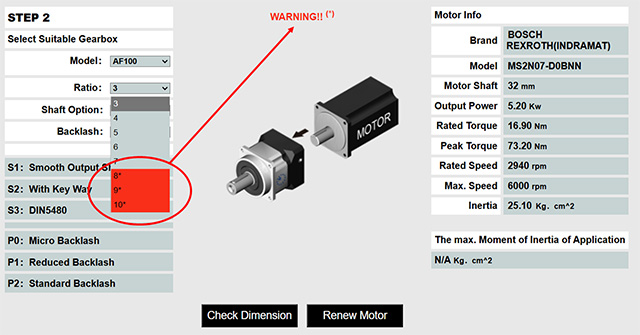

Why does the Apex Dynamics Design Tool sometimes not show the desired gear ratio?

This is usually due to excessive output torque in the selected combination. In this article, we explain how torque is calculated, the role of motor current limitation, and how you can still achieve a technically good solution without oversizing.

At Apex Dynamics, we regularly receive feedback that our Design Tool doesn’t display the desired gear ratio when selecting a gearbox in combination with a servomotor. While this may seem confusing at first, there’s almost always a technical explanation: the combination of motor and gear ratio generates an output torque that exceeds the gearbox’s allowable level.

This article explains step-by-step how torque is calculated, why the Design Tool excludes certain combinations, and how motor current limiting can be applied to arrive at a workable solution without having to immediately select a heavier – and often more expensive – gearbox.

Why doesn’t the Design Tool show the desired combination?

The Apex Dynamics Design Tool has been specifically developed to enable users to select the correct gearbox quickly and reliably.

- Whether the output torque (nominal and peak) remains within the gearbox’s limits

- Whether the speeds are not too high

- Whether the gearbox’s no-load torque is not too high for the motor

- Whether the motor’s mechanical dimensions to the gearbox’s input side is compatible

- Whether the motor has sufficient inertia in relation to the gearbox (for stability and dynamics)

In practice, however, the most common bottleneck is an output torque that is too high.

How is output torque calculated?

A gearbox multiplies the input motor torque by the gear ratio. This amplification is desirable to deliver more power to the output side, for example, when driving heavy loads. However, if this multiplied torque exceeds the gearbox’s capacity, it can lead to mechanical damage.

Below a Current Limiting Calculator, enter the gear ratio, nominal and maximum torque of both the gearbox and the motor and you will see by how much you need to limit (if necessary):

Current Limitation Calculator

Result

Nominal (T2N)

Calculated Motor Torque

10 NmCurrent restriction

0%Maximum (T2B)

Calculated Motor Torque

10 NmCurrent restriction

0%The calculation is as follows:

- T2N (nominal torque) = nominal motor torque × gear ratio

- T2B (maximum or peak torque) = peak motor torque × gear ratio

For example:

A servo motor with a nominal torque of 5 Nm and a peak torque of 15 Nm, combined with a gear ratio of 20:1, delivers:

- T2N = 5 × 20 = 100 Nm

- T2B = 15 × 20 = 300 Nm

For example, if the selected gearbox can handle a T2N of 90 Nm and a T2B of 250 Nm, then the combination will exceed both limits – and will not be shown in the Design Tool.

What is current limiting and how does it help?

In many cases, the output torque is theoretically too high, but in practice, the application doesn’t require that much power. It’s a waste to select a larger (and more expensive) gearbox. The solution? Limit the current supply to the motor.

The torque of an electric servomotor is directly dependent on the amount of current it receives. By limiting the current, the maximum torque the motor can develop—and therefore also the output torque of the gearbox—is limited.

This can be done in two ways:

- Limiting the nominal torque

In this case, the continuous current to the motor is adjusted so that the nominal output torque (T2N) is not exceeded. - Limiting the peak torque

The peak current – which is released during acceleration or sudden loads, for example – is also limited so that the output peak torque (T2B) remains within specification.

The condition is of course that the actual torque required in the application remains below the limited level.

Why is current limiting often the ideal solution?

- Prevents oversizing of the gearbox

- Cost savings: a smaller gearbox is more economical to purchase and install

- Space savings: compact design in limited installation space

- Better efficiency: smaller gearboxes often have a more favorable inertia

Applying current limitation does require some coordination with the manufacturer of the servo motor or drive amplifier. Modern controllers usually offer standard settings for limiting the current (and therefore the torque) via software.

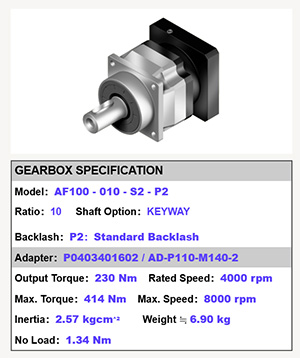

Practical example

A customer wants to combine a 40:1 gearbox with a servomotor rated at 6 Nm nominal and 18 Nm peak. The desired gearbox has a T2N of 200 Nm and a T2B of 400 Nm.

- T2N = 6 × 40 = 240 Nm → too high

- T2B = 18 × 40 = 720 Nm → much too high

By limiting the motor current torque to 5 Nm nominal and 10 Nm peak, the output torques are as follows:

- T2N = 5 × 40 = 200 Nm

- T2B = 10 × 40 = 400 Nm

These are exactly within the specifications of the gearbox – and the combination is therefore technically good, without any modifications to the mechanics.

What if te desired combination does not appear in the Design Tool?

If the Design Tool doesn’t show a result for a particular combination, this doesn’t mean it’s technically impossible. On the contrary: it means one or more values fall outside the standard limits, in which case current limitation could be a possible solution.

In that case, you can simply contact Apex Dynamics. We’re happy to review the calculation, explain the bottleneck, and advise on the best solution. If desired, we can also send you the technical drawing of the gearbox so we can continue working on the application immediately.

Conclusion

Correctly calculating the output torque is essential when selecting a gearbox. When this torque exceeds the gearbox’s capacity, current limitation is often an efficient and safe solution. This prevents unnecessary oversizing and allows you to still use the desired gear ratio.

Do you have questions about torque, gear ratios, or current limitation in combination with a servomotor? Feel free to contact Apex Dynamics – we’re happy to help!