What is backlash in a planetary gearbox?

In industrial drives, accuracy is crucial. One of the most important parameters influencing a system’s positioning accuracy is backlash—also known as torsional backlash. In this article, we explain exactly what backlash means in an Apex Dynamics planetary gearbox, how it’s measured, and why it’s so important in high-end applications.

What is backlash?

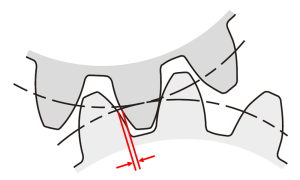

Backlash is the tooth flank play in a transmission when the input shaft changes direction and the output shaft does not yet move with it. It results from small gaps between the teeth of the gear mechanism.

In a planetary gearbox, this manifests as minimal but measurable rotational backlash on the output side when the input side is stationary or just changes direction.

Backlash is expressed in arcminutes:

- 1 degree = 60 arcminutes

- 1 arcminute = 60 arcseconds

How much is 1 arc minute in practice?

Although an arcminute is a small unit, the impact on an application can be significant, especially with long distances or large arms in robotics or positioning systems.

Example: play at 10 meters:

The deviation caused by 1 arc minute at an arm’s length of 10 meters can be calculated as follows:

- Circumference (arc length) = angle (in radians) × radius

- 1 arc minute = (1 / 60)° = (π / 10800) rad ≈ 0.000290888 rad

- Backlash = 0.000290888 × 10,000 mm ≈ 2.91 mm

So 1 arc minute of backlash results in almost 3 mm deviation at 10 meters distance.

At higher backlash (for example 5 arc minutes) this quickly becomes 15 mm.

Typical tbacklash at Apex Dynamics

Apex Dynamics levert planetaire tandwielkasten in verschillende nauwkeurigheidsklassen, waarbij de verdraaispeling per serie verschilt:

| Series | Type | Backlash (typical) |

| PII | Economy-series | < 8~12 arcmin |

| AB / AF /AD | High Precision | < 3~7 arcmin |

| AH / AP | Premium-series | < 1~2 arcmin |

These values were measured at 2% of rated output torque and a single-stage transmission. With multiple stages or higher ratios, the backlash may increase slightly.

Why is backlash important?

In many applications, a small amount of backlash is essential for accurate operation. Below are some applications where this is critical:

Robotica and cobots

Robotica and cobots

In a robotic arm, backlash can cause inaccurate tool positioning at the end. A small amount of axial play results in a large deviation at the end of the arm. This can be problematic for tasks like pick-and-place, welding, or assembly.

- CNC-machines

In milling or engraving machines, backlash partly determines repeatability and surface quality. Backlash causes deviations during rotational direction changes (e.g., when following contours), leading to inaccurate machining.

- Measuring equipment and vision systems

In applications like laser scanners or positioning systems with optical feedback, any deviation is noticeable. Especially when measuring over longer distances, even 1 arc minute becomes relevant.

- Packaging technology

Fast, repetitive, high-precision movements require a backlash-free drive to prevent wear, misalignment, or downtime.

- 3D-printers and additive manufacturing

Precision at each layer determines the final quality of the object. Any tolerances here lead to inaccurate layers or exceeding tolerances.

How to limit backlash?

At Apex Dynamics, backlash is minimized in several ways:

At Apex Dynamics, backlash is minimized in several ways:

- Precision Gear Manufacturing

Grinding, hardening, and precision machining ensure minimal tolerances between tooth flanks. - Use of bevel gears or helical gears

These ensure smooth, precise transmissions with reduced backlash. - Selecting the Correct Gear Ratio

Lower ratios generally have less cumulative backlash than higher ones. - Production Control and Individual Measurements

Apex Dynamics checks all A-series gearboxes for backlash.

How to choose the right gearbox based on backlash?

When selecting a gearbox, it’s important to consider not only torque and speed, but also backlash. Some questions to ask:

- What is the distance between the motor and the end application?

- Is precision more important than cost?

- Are there rapid direction changes?

- Is absolute or repeatable accuracy required?

In pick-and-place robots, for example, repeatability is crucial; a tolerance of 1 arc minute can be excessive.

In positioning applications with high repeatability, the choice of an Apex Dynamics premium series is often justified.

Summary

Backlash is a subtle but important parameter that affects the accuracy and performance of mechanical drives. In applications requiring positioning precision, even 1 arc minute can make a noticeable difference.

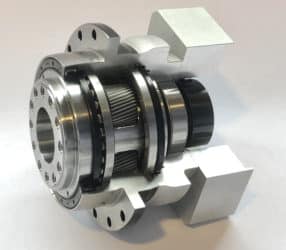

Apex Dynamics offers a wide range of planetary gearboxes with backlashes starting from less than 1 arc minute. A suitable solution is available for every application, from simple packaging machines to high-end cobots.

Contact our specialists or use the Design Tool for a direct selection based on your specifications.