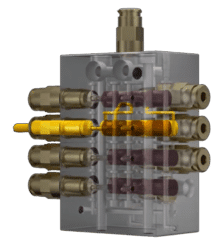

Automated CNC lubrication system complete with progressive distributor

A minimalistic, complete solution for the lubrication of all moving parts in a CNC machine? The fully automated lubrication system from Apex Dynamics with progressive distributor can handle up to 11 lubrication positions and, thanks to a pressure of 100 bar, cover up to 15 meters. In this article, we will discuss the extensively field-tested solution for the lubrication of CNC machines.

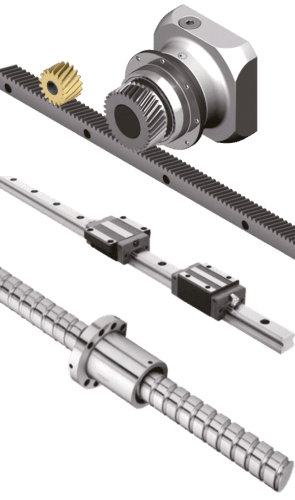

But in some applications, such as in a CNC machine, all these systems must be lubricated. How do you prevent over-lubrication or an excess of cables and hoses in the system due to multiple lubrication systems?

Progressive distributor CNC lubrication system

At 7 lubrication positions, it therefore lubricates to output 1 – 2 – 3 – 4 – 5 – 6 – 7 – 4. After this, the system restarts the cycle again. The progressive distributor contains plungers which are operated by the pressure in the system.

See the video below:

Optionally, the system can also be equipped with a sensor, which monitors the lubrication system and gives feedback of the operation to the PLC.

Pressure up to 100 bar standard covers 15 meters

Lubricant

A lubricant with a viscosity of NLGI 1 is recommended for this system. (Both NLGI 1 and NLGI 2 viscosities are available as cartridges for the lubrication system.)

Automated lubrication system CNC machine extensively tested

Would you like to know more about this fully automatic lubrication system and its application in CNC machines? Download the catalog here or contact us.