Calculate gearbox and linear motion for 3D printer in the construction industry

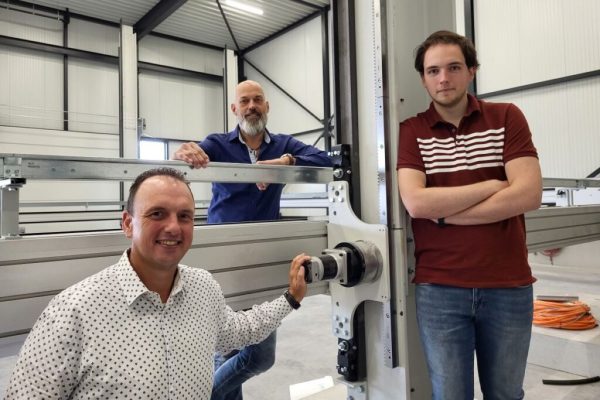

The latest edition of magazine Aandrijftechniek focuses on our collaboration with AXIS & Stuifmeel for client CyBe Construction. The pioneer of 3D printing in the construction industry counted on our expertise, not only around gearboxes but also our knowledge of racks and pinions. In the past we have already worked with AXIS Stuifmeel on Robot Crawlers, Corné van Gils says:

“We liked it so much that we eventually asked Apex Dynamics to help think about the linear movements of the gantry systems and the gearboxes for their drive. Because they are also familiar with pinions and racks, I asked Eric Megens to come and have a look at CyBe.”

The complete (Dutch) article by Paul Quaedvlieg can be read in the new edition of aandrijftechniek.

Calculate gearbox

Our very own Eric Megens told this about the challenge:

“The weight of the spray nozzle, the robot and the X and Y axes is carried by the drives in those eight columns. The calculation of this, with a special gearbox, caused many headaches. Another major challenge at the gantry was the calculation from the load to the servo motor. Since the ABB motors were already chosen, we now had to start calculating from the motor to the load. That works, but it does make it more difficult. Everything has to do with accelerations, forces and torques.”

Would you like to know more about determining the right servo motor and gearbox combination or the application of our rack and pinion systems? Please contact us!