Graduation project – From idea to realization

“We currently use a W22 IE3 three-phase electric motor with a nominal torque of 1.34 kgfm (approx. 13.1 Nm) and a nominal speed of 2900 rpm. However, for our application – grinding specific plates – a continuous torque of at least 250 Nm is required. The entire setup must be able to deliver this torque continuously for at least 20 minutes. The output speed after reduction is of secondary importance to us; achieving the required torque is our priority.”

This question led Tom van Hattum, an Automotive Engineering student at Fontys, to Apex Dynamics. In this article, he writes about his experience during the project.

– Tom van Hattum – For my graduation project at Fontys Automotive Engineering, we initially had a complete solution. Until we overlooked a crucial point: the electric motor, already incorporated into the concept, lacked torque by a factor of 20. What next?

– Tom van Hattum – For my graduation project at Fontys Automotive Engineering, we initially had a complete solution. Until we overlooked a crucial point: the electric motor, already incorporated into the concept, lacked torque by a factor of 20. What next?

When it turned out that the electric motor we wanted to use for the application had too little torque, but an unnecessarily high speed, the option of using a gearbox quickly emerged. After several conversations with Tutors and Professionals in the field, we found the Apex Dynamics website. Because we had many questions ourselves, we contacted them immediately.

Gearbox selection

Initially, we knew the gearbox needed a 20:1 ratio. The reason for this was that the electric motor only delivered 13 Nm of torque, while we needed at least 260 Nm. Furthermore, the motor’s speed was far too high for our application.

After presenting this problem, along with several other requirements, to Thom and Stef van Oss, they quickly came up with a suitable solution: the Apex Dynamics AE120-020. This gearbox would increase the torque to the desired 260 Nm. Thanks to the included 3D renderings, we were able to quickly incorporate the gearbox into our concept. The smooth and rapid communication with Apex Dynamics allowed us to integrate the solution effectively and on time.

Installation process

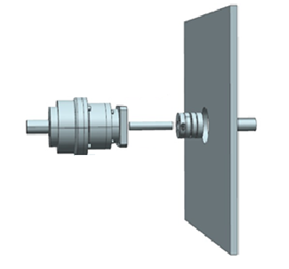

Apex Dynamics indicated that a gearbox is typically mounted directly to an electric motor. However, due to the specific motor configuration in our project, this wasn’t possible. Thanks to Apex Dynamics’ input and consultation, we arrived at an alternative solution: the gearbox was mounted on a steel plate positioned in front of the electric motor.

This configuration required an additional shaft between the electric motor’s output shaft and the gearbox’s input shaft. Apex Dynamics proposed using one of their new disc couplings for this purpose, which could be used to connect a stub axle to the electric motor’s output shaft. This stub axle was then connected to the gearbox.

A disc coupling was also used on the output side of the gearbox to connect it to the rest of the drivetrain.

Usage

After installing all the components, we can confidently say the system is functioning perfectly. The gearbox we used completely solved the low torque issue, allowing us to continue using the original electric motor in our application.

The gearbox’s commissioning went smoothly. Thanks to the expert support of Thom and Stef van Oss, we were able to achieve a highly effective and well-thought-out solution together.

The combination of the gearbox with backlash-free disc couplings results in a robust and reliable drivetrain.

Tom van Hattum I Fontys Automotive Engineering

Apex Dynamics BV regularly supports students like Tom with advice and the right mechanical drive components, contributing to their personal development and the future of technology.