Why helical gear racks are (often) our preference

Why do we prefer helical racks and pinions? Many customers think that helical racks are more expensive, but this is not true. There is a very good reason to go for helical racks. In this article we explain where the price misunderstanding comes from, what the technical differences are and explain why we often recommend a helical rack and pinion system.

Helical racks more expensive? A misunderstanding

In the past it was indeed much easier to make a straight-toothed rack and pinion, because the milling and grinding machines were often mechanical and had to be adjusted manually. Then making a helical rack is more difficult, because it requires accurate setting and adjustment of the machines. These machines have almost everywhere been replaced by CNC machines for which producing helical or straight teeth makes no difference at all.

In the past it was indeed much easier to make a straight-toothed rack and pinion, because the milling and grinding machines were often mechanical and had to be adjusted manually. Then making a helical rack is more difficult, because it requires accurate setting and adjustment of the machines. These machines have almost everywhere been replaced by CNC machines for which producing helical or straight teeth makes no difference at all.

At Apex Dynamics, the prices for straight-toothed or helical racks are therefore almost the same. Of course, we have the latest generation of milling and grinding machines in our production, these are German, Austrian or Swiss made and have fully automatic teething according to the Klingelnberg standard.

Technical differences between helical and straight racks

So the price is almost the same, but are there technical differences? Below is a table with the most important parameters:

| Straight | Helical | Remark | |

| Lateral force | No | Yes | The lateral force is F2ax-mu*F2ax, and is absorbed by the guide |

| Troque | 100% | 120% | A helical tooth has a longer length, which means more torque. |

| Number of teeth in contact | 1 | 2,2 | More teeth in contact means higher torque and more crash resistance |

| Backlash | X | X | Equal quality means equal play |

| Noise | – | + | Helical gears are much quieter |

| Price | 100% | 100% | Almost equal |

But watch out! The above information is not the main reason to go for helical racks.

Why helical racks

Suppose you want to make a track 10 meters long, with racks from module 2. The pitch between the teeth is rounded pi x m = pi x 2 = 6.283185307179586. The rack is a multiple of the tooth pitch and that is 160 teeth for a rack of 1 meter. A straight toothed rack of 1 meter is therefore 1.005.3096…. mm long.

Suppose you want to make a track 10 meters long, with racks from module 2. The pitch between the teeth is rounded pi x m = pi x 2 = 6.283185307179586. The rack is a multiple of the tooth pitch and that is 160 teeth for a rack of 1 meter. A straight toothed rack of 1 meter is therefore 1.005.3096…. mm long.

If you want to mount this rack with, for example, 8 bolts, the pitch between the holes will be 1,005.3096…. / 8 = 125.663706143592…. In other words, stitch spacing is not a round number.

What happens now during the pre-processing of the 10 meter long track?

The CNC machine will drill and tap the mounting holes and round this fractional number to, for example, 125.66 mm. Over 10 meters and 8 holes per meter the rounding error is 0.003706143592 x 10 meters x 8 holes per meter = 0.326 mm. This means you run a considerable risk of not being able to install the (last) racks!

The solution

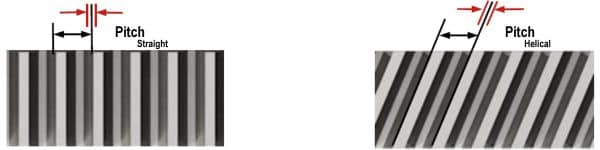

To solve this problem, a simple as well as ingenious solution has been devised: If I place the teeth at an angle, the distance between the teeth in the longitudinal direction of the rack changes and I can thus influence the length. (After all, the tooth pitch is always measured perpendicular to the tooth flank.)

Suppose I want 150 teeth and the length of the rack is exactly 1000 mm, then the tooth pitch in the longitudinal direction is 1000/150 = 6.66666666667 mm. the tilt of the teeth then becomes Cosinus alpha = 2 x pi / 6.6666666666667. Alpha is then rounded to 19.528 degrees, or 19g31’42”. Now you can drill 8 holes on the rack at exactly 1000 mm / 8 = 125 mm. The error no longer occurs in the pitch of the mounting holes but is now in the corner of the teeth. And it doesn’t cumulate!

Because the teeth on Apex are reground somewhat “convex”, it corrects any small angular deviation between the rack and pinion. We call this the Heli-topo technology.

The main reason for helical gearing – especially in longer systems – is the round pitch of the mounting holes!

Footnote: To get a tooth pitch with an integer number you could also adjust the module. That is why Apex Dynamics can also supply straight-toothed racks with a module of 1.591; 3.183 and 4.244 mm for a round tooth pitch of 5, 10 or 13.333 mm. (the stitch is pi * module).

However, the range of racks and pinions with this module is generally much smaller, which is why they have a higher price than straight or helical racks and pinions with a round module.

Need support?

Could you use some help or support? Or do you simply have a question about racks and pinions? Please contact our team on +31 (0)492 509 995 or send an email. We always answer emails quickly and accurately.